Smart Food Monitoring System on Biodegradable Packaging

Design and investigation of a simple sensor circuit intended for smart food monitoring system on biodegradable packaging using Sonali Bag® technology.

Project Overview

The EEE 4861 assignment investigates how smart sensing can be embedded within biodegradable packaging to improve food safety in Bangladesh. Our team designed and analyzed a MOSFET-based temperature monitoring circuit that can be fabricated through a VLSI workflow and embedded into Sonali Bag® packaging to detect unsafe temperature excursions for perishable goods.

Motivation

- Widespread reliance on conventional plastic packaging continues despite Bangladesh’s 2002 polythene ban

- Retailers cite low cost, convenience, and limited biodegradable alternatives as barriers

- Smart packaging can curb post-harvest losses, improve food safety, enhance traceability, and reduce waste through proactive alerts

Critical Challenges

- Conventional barcodes offer billing convenience but no quality assurance

- Biodegradable substrates are costlier and harder to integrate with electronics in low-income contexts

- Limited public awareness of food safety practices complicates adoption

Literature Review Highlights

- Bangladesh Context: Enforcement gaps, lack of affordable alternatives, and low consumer awareness hinder the 2002 polythene ban

- Biodegradable Options: Surveyed mushroom, bamboo, algae-based, sugarcane fiber, coconut husk, wheat straw, PLA, starch, chitosan, and cellulose materials

- Key Trade-offs: Cost, mechanical strength, biodegradation timeframe, scalability, and moisture resistance

Selecting Sonali Bag®

- Indigenous jute-based biopolymer pioneered by Bangladeshi scientists; production cost around Tk. 1200/kg

- Demonstrated biodegradation within 100 days without toxic residue

- Thermal stability up to 250 °C and controlled degradation characteristics

- Aligns with local supply chains, policy goals, and consumer familiarity better than alternatives (e.g., Polka Bags, corn starch)

Sensor Circuit Design

- Electronic temperature monitoring chosen for precision, low power, and digital compatibility

- All-MOSFET architecture minimizes area (≈0.013 mm² in 180nm CMOS including reference) and power (≈40 nW @ 1.2 V)

- Achieves ±0.6 °C inaccuracy without calibration; suitable for smart packaging, room monitoring, refrigeration, and automotive use cases

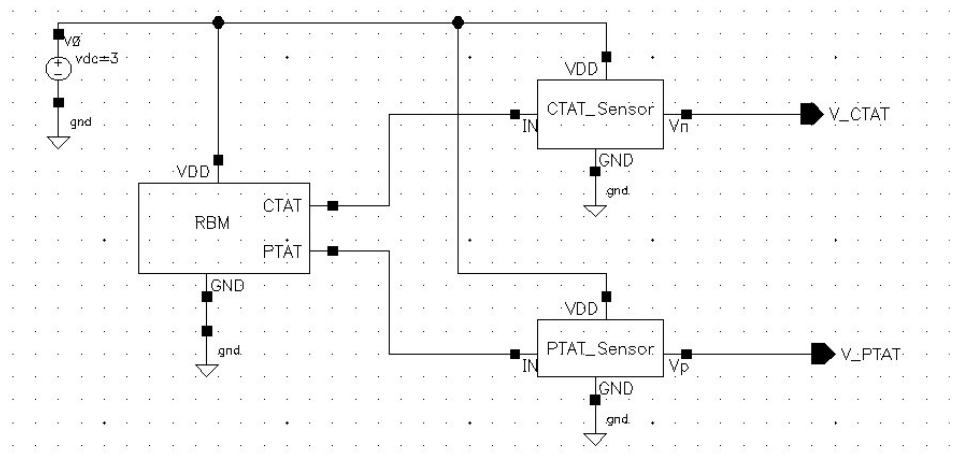

Complementary Temperature Sensor Workflow

- Reference Current Generator: Resistor-less beta multiplier provides PTAT current to both sensing cores

- CTAT Core: NMOS transistors in subthreshold produce voltage decreasing with temperature (≈−2.1 mV/°C)

- PTAT Core: PMOS configuration generates proportional output increasing with temperature

- Differential Readout: Temperature calculated from VPTAT − VCTAT, cancelling process variations and enabling calibration-free operation

- Signal Processing: External ADC digitizes readings; microcontroller maps voltage difference to temperature thresholds

Integration with Biodegradable Packaging

- Embed the temperature sensor within Sonali Bag® layers for direct exposure to food environment

- Use MOSFET-based threshold detection to drive LED or buzzer alerts when temperatures exceed safe ranges

- Multi-level cues: normal (no alert), warning (blinking LED), alert (solid LED), critical (buzzer)

- Maintain moisture protection for electronics while keeping indicators accessible

Decision-Making Framework

- Step 1 – Monitoring: Continuous temperature sampling tailored to food type

- Step 2 – Alerting: Trigger visual/audible cues when thresholds are crossed

- Step 3 – Action Guide:

- < 2 h exposure: consume immediately or refrigerate

- > 2 h exposure: dispose responsibly

- Disposal: Compost both food waste and Sonali Bag® when feasible

- Priorities: Human health → Environmental stewardship → Cost feasibility

- Regulatory Alignment: Supports Bangladesh Environmental Conservation Rules 2023 via better waste management, reduced pollution, and consumer education